22mm impact test|weighted hammer impact test : broker In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa. WEB31 de dez. de 2023 · Com o Redcine APK, você pode assistir TV, filmes e séries de alta qualidade no seu celular ou na sua TV Box, sem travamentos ou quedas de resolução. .

{plog:ftitle_list}

WEBBem-vindo ao Site de Acesso Restrito do MPF — Acesso Restrito. Você está aqui: Página Inicial.

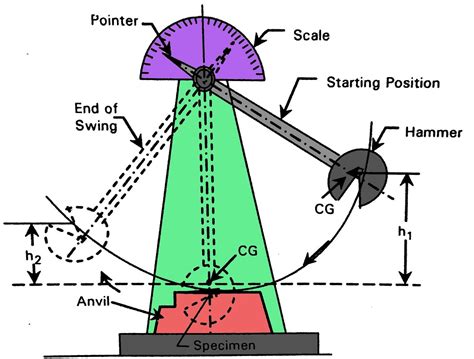

These plastic impact test methods measure the energy absorbed by the specimen caused by the impact to create failure. These test are typically pass/fail tests: They give the average impact energy required to break the samples. . An impact test is a technique used to determine a material’s ability to resist deformation when subjected to a sudden shock or impulse load. There are several different types of impact tests, but all entail striking a .The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a good .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is . The 50 kN capacity and the fully variable test speed of 0.2 to 51 mm/min make it possible to perform not only the CBR and Marshall tests, but many other applications as for instance Indirect Tensile test, Quick Triaxial .

dm feuchtigkeitsmessgerät testsieger

Maximum impact energy 450J Pendulum pre-elevation 150° Minimum angle resolution 0.025° Distance between pendulum center and impact point 750 mm Impact speed 5.24 m/s Strike blade radius 2 mm or 8 mm Dimension of the main tester (W x H x D) 2240 x 902 x 2145 mm Weight 1200 kg Impact test result, digital displayISO Impact energy (kJ)

If impact testing is carried out over a range of temperatures the results of energy absorbed versus temperature can be plotted to give the 'S' curve illustrated in Fig.3. . B31.3 for example requires a lateral expansion of 0.38mm for bolting materials and steels with a UTS exceeding 656N/mm 2, rather than specifying an impact value. Procedure of Impact Test. The procedure of the impact value test includes the following series of steps: 1. The aggregate samples of size 10mm to 12.5mm (passing through 12.5mm sieve and retained on 10mm sieve) are first taken and oven-dried at a temperature ranging from 100 degrees Celsius to 110 degrees Celsius for about four hours . HAM decided to test the FX Impact in a fairly basic – and likely typical – specification. We took the gun from Airguns of Arizona in .22 caliber, attached HAM Tester Doug Rogers’ own Hawke 4.5 – 14 x 42 Sidewinder scope and set the power to maximum. In this form, the FX Impact costs a cool ,999.99 for gun alone.

In accordance with to the ISO 180-2000 standard (ISO 180 2000), notched Izod impact tests are carried out.The impact behavior of polycarbonate specimens is analyzed. Rectangular plates of polycarbonate Lexan 141R, with dimensions 170 × 70 × 3.2 mm 3, are injection-molded.The melt temperature and the injection velocity are set to 295°C and 30 cm 3 /s respectively.

Izod impact tester in Blists Hill Victorian Town. The Izod impact strength test is an ASTM standard method of determining the impact resistance of materials. A pivoting arm is raised to a specific height (constant potential energy) and then released.The arm swings down hitting a notched sample, breaking the specimen. The energy absorbed by the sample is calculated .Charpy to ISO 179-1 is the preferred test method on plastics within the standard for single-point data ISO 10350-1. The test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens.Husky 1/2 in. drive Impact Sockets are manufactured from chrome molybdenum alloy steel and designed to withstand rigors of heavy duty use. Size markings have been hard stamped into the sockets for quick . mm impact wrench sockets. 22mm impact socket. husky 22 miillimiter socket. 22mm 3/8drive impact socket. Related Products. 1/2 in. Drive 3/4 .

ASTM D256 outlines the Izod impact test for plastics, emphasizing specimen preparation and machine calibration for accurate impact resistance data. . has stated that it is essential that the notched surface be machined parallel to its opposite surface within 0.0025 mm (0.001in.)” for injection molded specimens in order to eliminate the high .variation of impact strength with temperature. Observations: (a)dimensions of the specimen 55 mm 10 mm 10 mm (b)notch width 2 mm (c)area under the notch 80 mm2 (d)maximum possible energy value 406 J (obtained from machine) (e)energy loss due to friction 2.0975 J (obtained from machine) Sr. No. Material EMF (mV) Temperature (oC) Impact Energy (J) izzod method impact test, the pendulum stroke is directed at a distance of 22 mm from the clamp and the notc h is facing the pendulum. Impact Test Analysis on Steel Metal Materials and Aluminum

For example, when impact tests are required as part of the classification of an electrode, they are machined from the same test weld as the tensile specimens. The test plate is 20 mm thick and the impact specimens are located mid-thickness as shown in Figure 4 below. The notch is placed perpendicular to the plate surface on the centreline of .

Within 22 mm Impact Sockets, socket sizes range from 0.220 in to T50. Check out this popular option 3/4 in. Drive Hex Bit Impact Metric Socket 22 mm. Related Searches. milwaukee socket set. milwaukee impact socket set. socket set. milwaukee 3/8 impact sockets. 4 .The impact test can indicate if the material is extremely brittle. It also tells us if a material has undergone the right heat treatment or not. . If in an old test, energy absorbed (obtained on the scale) is 34 J and cross-section area of the notch is .

Impact is also a leading manufacturer of test sieves within the UK, Impact has been supplying to engineering, mining, chemical, pharmaceutical, agricultural and food industries for over 20 years, and are proud to have a reputation for supplying quality products and excellent service.The standard Charpy impact test specimen is of dimension 55 mm × 10 mm × 10 mm, having a notch machined across one of the larger dimensions, as illustrated in Fig. 1.3. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load [10] .

Find the right pendulum impact testing machine for your test requirements Pendulum impact testing machines for metals and plastics Detailed information Applications More information. . mm: Impact velocity: 5.42: m/s: Weight, approx. Machine frame 510: kg: Safety device: 180: kg: Concrete base: 2520: kg: Total, without pendulum hammer: Izod Impact Test (Notched Izod) - ASTM D256 and ISO 180 The Notched Izod Impact Test is a crucial method used to gauge a material's resistance to a swinging pendulum's impact. . Specimen Specifications for Testing. Dimensions: 64 x 12.7 x 3.2 mm (2½ x ½ x 1/8 inch). Standard thickness: 3.2 mm (0.125 inch). However, 6.4 mm (0.25 inch) is .

what is an impact test

The standard size of a specimen for Charpy impact testing is 10 mm × 10 mm × 55 mm. A 2mm deep notch with an angle of 45° and a tip radius of 0.25mm is then machined into one face of the bar. These specifications have a very tight tolerance because the shape and size of the notch can have a significant effect on the results of the test. Charpy impact test results are measured in joules, the SI unit for energy. . However, in general, the sample size is 55 x 10 x 10 mm with a V-notch machined in the middle of the sample. The exact shape of the notch is also indicated in the relevant standard. The testing standard will also dictate how many samples must be tested.Cement wet washing sieves are now available from Impact, with replaceable stainless steel mesh and Wet Washing Sieve Apparatus to ASTM C430, ASTM D1514; AASHTO T192. Sieve Selector. Civil Engineering Test Equipment. Impact is also a manufacturer and supplier of laboratory testing equipment for the civil engineering & construction industry. This video is a full review and accuracy test of the FX Airguns Impact M3 air rifle. This precision pellet rifle can be adjusted to shoot any pellet with ext.

dns feuchtigkeitsmessgerät

ImPACT is a computerized concussion assessment tool for ages 12-59. By comparing baseline and post-injury ImPACT test results, you can make confident treatment decisions.

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount .Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally in the Charpy impact testing machine. The Charpy impact test specimen notch faces away from the pendulum, which swings down from a set height to strike the sample.

weighted hammer impact test

types of impact testers

Resultado da See Instagram '殺殺 ' highlights from Mirian Gabriela conta nova (@soyrouzyy_1) See Instagram '🥰🥰 ' highlights from Mirian Gabriela conta .

22mm impact test|weighted hammer impact test